Bio-Conversion/Fermentation

Information

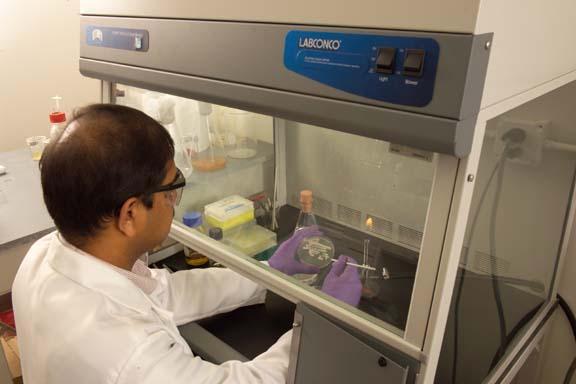

The Fermentation Center at BIVAP provides research, technical service, and education of fermentation technology.

With a highly experienced staff and state-of-the-art facilities, the fermentation team has the resources and capabilities to develop processes for converting a variety of agricultural co-products and waste streams. This includes: starches, cellulose, and lignocellulose to form 2-carbon (C2) products (such as ethanol), as well as C3 and C4 platform products, and organic chemicals that are used as building blocks for energy or processed to produce a variety of consumer products. In addition, we develop better technologies for pre-processing agricultural raw materials to reduce complex carbohydrates into C5 and C6 sugars that can be fermented through familiar microbiological routes. The U.S. Department of Energy has identified twelve building block chemicals that can be produced from sugars via biological or chemical conversions in “Top Value Added Chemicals from Biomass.” The twelve building block chemicals can be subsequently converted to a number of high-value biobased chemicals or materials. Building block chemicals, as considered in the Department of Energy analysis, are molecules with multiple functional groups that possess the potential to be transformed into new families of useful molecules. This document provides a roadmap for chemical conversion of biomaterials to value-added chemicals that link into conventional chemical pipelines existing within established markets from the petroleum industry. Escalating cost for petroleum feedstock makes this an attractive approach to conversion of currently available agricultural biomass into higher value products with established market channels.

Services

- Pretreatment of agricultural feed stocks: thermal, chemical, and enzymatic processes

- Generation of glucose stream from renewable sugar sources

- Screening and adaption of microbial strains for production of high yield target molecules, including metabolic engineering of selected strains

- Product development through challenging fermentation processes

- Scale-up, process integration, and optimization of promising technologies

- Post-fermentation operations, separation studies, water and waste minimization strategies

- Process development, flow-sheets, and development of economic and business models for emerging technologies

- Licensing and negotiation for commercialization of technologies